What does Silver Sage Precision do?

We supply mechanical design, R&D first article builds, mechanical fabrication coordination, construction and production of surface defect monitoring systems.

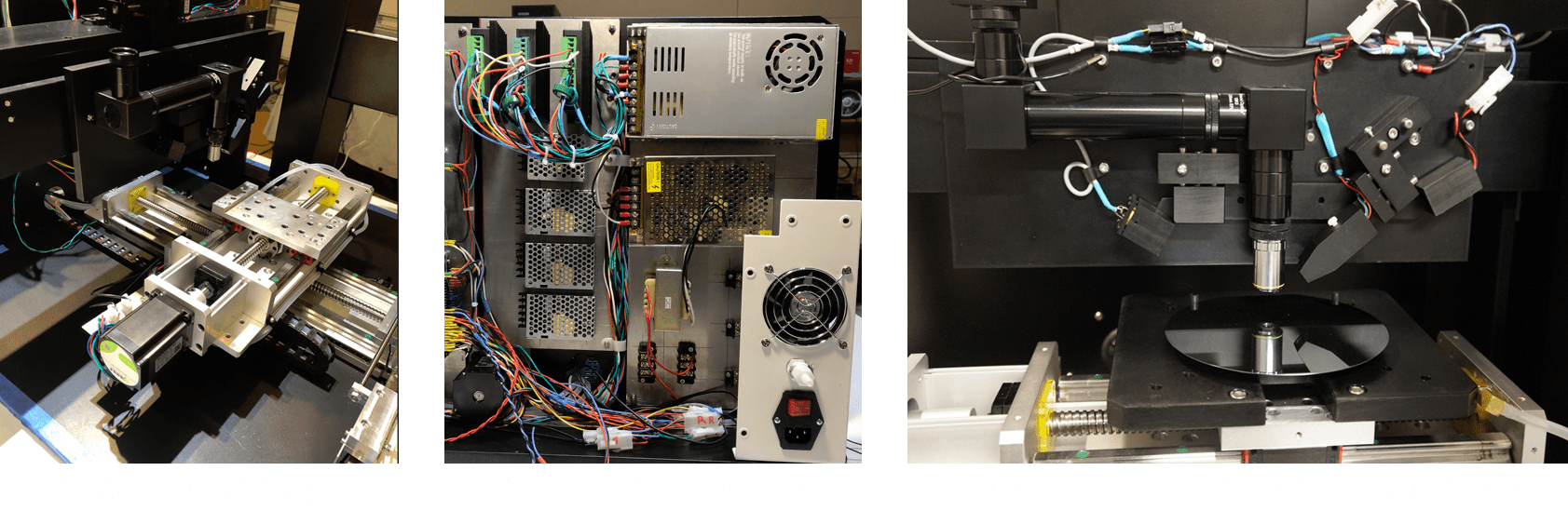

SDM-100 Shown

Why is Silver Sage Precision unique?

We manufacture a compact system:

- That produces reliable, accurate and precise positioning of samples to enable repeatable measurement data for process monitoring and troubleshooting

- That is simple to operate, dependable, easy to maintain and has a very low cost of ownership

- That even the smallest semiconductor industry businesses can afford to buy, use and maintain

SDM-100 System

- Concept of Use

- Single wafer measurements (4” to 12” capable)

- Manual load/un-load

- Table-top workspace with basic utilities (power, vacuum)

- Concept of Target Users

- Tool manufacture to validate tool cleanliness

- R&D Lab engineers to monitor process development cleanliness

- Process equipment engineers to validate tool cleanliness

- Process production engineers for inline SPC sampling of monitor wafers

What are the benefits of the components used in the system?

The systems active components (stages, motors, drivers, power supplies and lasers) are selected for long service life and sourced from common technical catalogs. We support the RIGHT TO REPAIR by providing all the purchased component information, part numbers, and specifications.

Meridian, Idaho